waelzlager

"We carry bearings of FUD, NSK, RHP, SKF, FAG, INA, ZYS, KRW, etc. brands.

" Ball bearings and roller bearings

"FUD, NSK, SKF, INA, FAG, ZYS and many more...

Rolling bearings for industry and trade

Fröhlich & Dörken offers you a wide range of bearings for the OEM market (Original Equipment Manufacturer) and the MRO market (Maintenance, Repair and Operations). As a ball bearing manufacturer, we offer our own bearings under the FUD neutral brand at a very favorable price/performance ratio. In addition, as an authorized dealer, we offer you all products from the NSK factory. NSK Deutschland GmbH has its headquarters in Ratingen. We can access the NSK stock directly online. Other brands such as ZYS, KRW, SLF, SKF, FAG, INA, etc. round off our range.

Are you looking for linear technology? Take a look at the Linear Motion Technology section. There you will also find NSK carriages.

Rolling bearing brands

NATHANAEL ALIUS

Sales Manager

We supply all well-known brands, such as FUD, NSK, SKF, FAG, INA, ZYS, KRW etc. We stock the whole range: deep groove ball bearings, taper roller bearings, spindle bearings, spherical roller bearings, plummer block housings, and more. Some of ourB2Bindustrial and wholesale customers need alternatives to the well-known brand manufacturers. As a distributor and ball bearing manufacturer, we are available for the well-known brands and for our own brand FUD we are a recognized supplier for our major customers. We have many product groups in stock at any time in our central warehouse in Sprockhövel, so that a fast delivery directly to your production or warehouse is possible. The catalogs can be found at the bottom of this page. The program is constantly being expanded.

NATHANAEL ALIUS

Sales Manager

Rolling bearings from FUD

Let us convince you of our high-quality rolling bearings. Do you need advice? Our team of experts will be happy to help you!

To ensure that we achieve your goal of maximum durability and efficiency at favourable conditions through the perfect mix of the right load rating, environmental characteristics and the right speed, we are at your side as a reliable partner with 75 years of experience with bearings and linear technology.

Quickly and easily find the most suitable and competitively priced rolling bearings from FUD for your individual use.

Whether you have a recurring need for your production and workshop or whether you are facing an individual challenge, our experienced expert advisors are at your disposal with a precise solution.

From our experience in advising our long-standing customers, we know that the quality and thus the service life of the component are the most important factors when selecting the right rolling bearing. By selecting the right materials and lubricants, we find the right bearing for your individual requirements.

Should you ever have an individual requirement for your rolling bearings, you can count on our experience in cooperation with engineering offices. This makes it easier for you to find a direct solution and creates plannability, e.g. in your production.

NATHANAEL ALIUS

Sales Manager

" Find your rolling bearing in our catalogue according to DIN - tell us your type designation directly

NATHANAEL ALIUS

Sales Manager

" Again and again, our customers ask these questions about rolling bearings and their use

NATHANAEL ALIUS

Sales Manager

Which rolling bearing is the right one for your purpose in terms of design and individual conception depends on various factors. The forces acting and the type of load are important influences.

Is it an axial force that acts or do radial forces arise? Is there a high or rather low speed in the area of application?

The load rating is another decisive factor to avoid unnecessary damage to your machines or equipment and to enable long service life. Environmental influences such as temperature or the proportion of dirt particles in the air are also important. How much may the component weigh and what installation space is available?

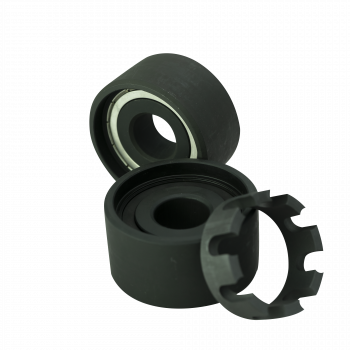

Depending on the application, the housing and all other components of the rolling bearing can be made of different materials.

For the shaft, there are different types of oil seals that seal the component from the environment. This avoids contamination of the housing. A distinction is made between axial and radial shaft seals. They keep the shaft tight in the long term to ensure a particularly long service life.

As a ball bearing manufacturer, we advise you on the ideal materials that match the properties for your application and are cost-effective. In this way, FUD ensures that in the end the price is right and you get the best possible quality. It can be a good solution to make parts of the component, such as the cage or housing, out of plastic. This is lighter than metal.

Together with the experts from FUD, find the right design based on the influencing factors of your requirement.

NATHANAEL ALIUS

Sales Manager

In addition to trading in rolling bearings from well-known manufacturers, FUD offers you even the most unusual individual solutions in cooperation with an engineering office based on your drawing.

This approach not only saves you time through the FUD experience in finding solutions, you also avoid problems and unexpected failures in the test or later use phase of your machines or components.

In addition, FUD carries out tests that check the expected characteristics of the design so that you can be sure that your expectations are fully met.

NATHANAEL ALIUS

Sales Manager

Rolling bearings are among the most frequently used machine elements where two fixed components are to be movably connected to each other. An example that is certainly familiar to everyone is a shaft that transmits force via a rotary movement and thus enables this movement with some form of rolling bearing. In the case of a roller skate or inline skate, the theoretical principle is the same as in the construction of equipment.

A distinction is made between three types of rolling bearings

Axial bearing: only absorbs forces acting parallel to the axis of rotation and cannot build up a counterforce to radially acting forces.

Radial bearing: only absorbs vertically acting forces and cannot build up a counterforce to axially acting forces.

Combined radial-axial bearing: can build up a counterforce to both radial and axial forces. It supports forces in both directions of action.

Call the FUD technical advisors and get the right solution immediately

NATHANAEL ALIUS

Sales Manager

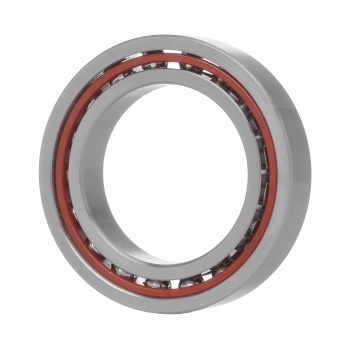

A rolling bearing transmits motion, i.e. it brings together components that move against each other. The built-in inner and outer ring provided with movable balls or rollers reduces the frictional resistance and leads to a more durable construction of the component by reducing friction. Depending on the direction and load of the occurring forces, balls or rollers are used.

NATHANAEL ALIUS

Sales Manager

Rolling bearings consist of an outer ring, an inner ring, a cage and rolling elements.

Assembly of deep groove ball bearings: The balls are inserted into the outer ring in contact with each other. The inner ring inserts eccentrically and is pressed down so that it is concentric. Now the balls are distributed at constant intervals. Finally, the cage is inserted to prevent the balls from rubbing against each other. If the rolling elements used are rollers, the principle works in the same way. Depending on the direction and load of the occurring forces, balls or rollers are used.

In addition to the design of the rolling bearing, the lubricant used and the quality of the steel of the individual components are also important.

NATHANAEL ALIUS

Sales Manager

Rolling bearings have the advantage of low friction, which means that the heat developed as well as mechanical wear are low. The lubricant requirement is low, making them easy to care for and maintain. They can transmit higher speeds than plain bearings and can conduct three-dimensional forces, unlike linear technology components that only allow movement in opposite directions.

For example, if you have a high load in a small installation space and low speed at the same time, a plain bearing would be a better choice.

NATHANAEL ALIUS

Sales Manager

Our customer was using plain bearings that generated too much friction. The electric motors of the plant were loaded in such a way that there was increased motor damage. FUD recommended a rolling bearing to the customer, which reduced the rotational resistance of the motor. This significantly reduced energy consumption and increased the service life of the electric motors by 30%.

NATHANAEL ALIUS

Sales Manager

Depending on the application, requirements and environmental influences, rolling bearings and their balls or rollers are selected. In addition to balls and rollers, barrels, needles, cylindrical or tapered rollers can be used.

This in turn leads to a particularly long service life of the components and thus of the entire machine and also to significant energy savings. Seals are used to keep lubricants inside the housing body and dirt particles outside.

The rolling elements all have the task of generating rolling friction and thus preventing the sliding friction that leads to wear, so that as little energy as possible is lost in the conversion and guidance of forces through the component, which at the same time reduces temperatures and minimises mechanical wear.

According to the load direction, there are the following types of bearings

Axial bearings have the task of withstanding forces in the direction of the shaft. They are optimally suited for low speeds. A distinction is made between single direction and double direction axial bearings.

Radial bearings are used when radial forces are transmitted. In many cases, a radial bearing has the property of transmitting axial forces slightly. Radial bearings include deep groove ball bearings, cylindrical roller bearings, needle roller bearings and spherical roller bearings.

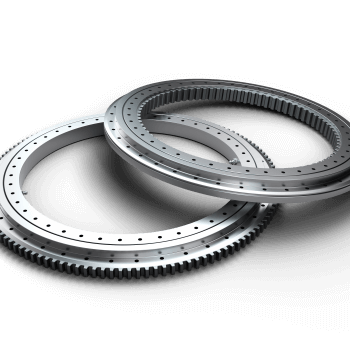

There are six different basic forms of rolling bearings

Ball bearings are the most commonly used form of rolling bearing as they offer the widest range of different dimensions. In addition, ball bearings are very cost-effective.

Tapered roller bearings can support very high loads in the radial and axial directions. As a rule, they are installed in pairs.

The cylindrical roller bearing is characterised by its large radial load carrying capacity.

Due to their design,toroidal roller bearings can simultaneously fulfil the function of a cylindrical roller bearing and a spherical roller bearing. They compensate for axial and angular misalignment by means of appropriately shaped rolling tracks without increasing friction.

A needle bearing has needle-shaped rolling elements with a large length compared to the diameter of the rolling element.

Spherical roller bearings are primarily designed for high impact-type radial forces. They are suitable for compensating misalignments.

The type of bearing that is right for you depends on what you want to use it for. The load and speed play an important role. Equally important for the right choice are temperature, vibration, lubrication, installation and maintenance. Other important questions are the type of load the bearing will take. Is it axial and radial forces, or is it a combination of different loads? The available space is also a decisive factor in selecting the right component. Let our expert staff advise you.