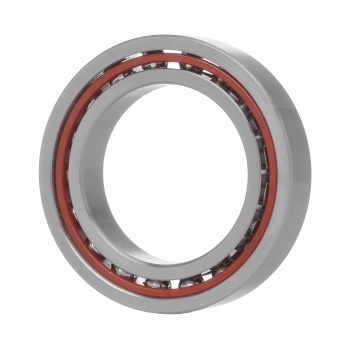

Seit vielen Jahren lassen wir Wälzlager und Lineartechnik nach unseren Vorgaben weltweit fertigen. Dabei unterscheiden wir Sonder- und Standardwälzlager.

FUD specific – sind Sonderwälzlager, die nach ihrer Zeichnung ganz spezifisch für Sie gefertigt werden. Wenn Sie also besondere Geometrien, Spezialkäfige, Sonderfette oder andere spezielle Anforderungen haben, sind sie bei uns genau richtig.

FUD specific für ihre speziellen Anforderungen!

Unsere über 75-jährige Erfahrung im Bereich der Antriebstechnik fließen in unsere Produkte. Unsere Spezial Wälzlager FUD specific werden von namhaften Erstausrüstern (OEM) seit vielen Jahren erfolgreich verbaut. Unsere Qualität hat sich im Markt bewährt.