"I will be happy to advise you to find the best solution for your individual requirements. Contact me, I look forward to a personal conversation!"

"We carry bearings of FUD, NSK, RHP, SKF, FAG, INA, ZYS, KRW, etc. brands.

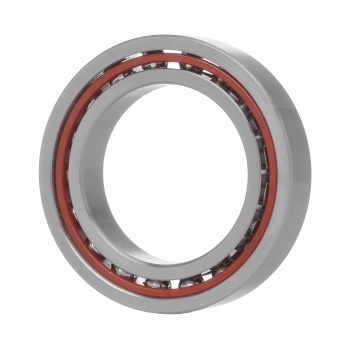

How to choose the right rolling bearing/ball bearing for a specific application?

When selecting the right ball bearing, the following aspects should be considered:

- Loads and stresses: Determine the radial and axial loads to which the bearing will be subjected. The load carrying capacity of the bearing should exceed the expected loads.

- Speed: Consider the rotational speed of your application. High speeds require bearings with special lubricants and designs.

- Environmental conditions: Your working environment, temperature, humidity and dirt can influence the choice of the right bearing. Corrosion resistant bearings are required in aggressive environments.

- Accuracy: Bearings with higher accuracies of form and position tolerances are required for precision applications.

- Alignment: If your shafts or axes are not perfectly aligned, self-alignment functions of the bearing may be necessary.

- Type of application: Different types of bearings are required depending on whether the load is radial, axial, combined or linear.

What factors influence the service life of a ball bearing?

Factors that influence the service life of rolling bearings/ball bearings:

- Loads and speed: Higher loads and speeds can reduce service life.

- Lubrication: Proper lubrication is critical. Incorrect or insufficient lubrication can lead to premature wear.

- Contamination: Dust, dirt or foreign bodies in the bearings can disturb the tribological properties.

- Corrosion: Moisture or aggressive environments tend to corrode bearing components.

- Mounting quality: Improper mounting can lead to premature wear or damaged bearings.

How is the mounting and maintenance of ball bearings/rolling bearings carried out?

Assembly and maintenance:

- Mounting: Make sure that the bearings are properly mounted in the housings and on the shafts. Use appropriate tools and methods to avoid damage.

- Lubrication: Use the recommended lubricant and observe the lubrication intervals. Excessive lubrication can be as harmful as insufficient lubrication.

- Seals: Seals protect against dirt and moisture. Keep them in good condition and replace them when necessary.

- Inspection: Monitor the condition of the bearings regularly. Pay attention to unusual noises, vibrations or heating.

- Replacement: Replace bearings in a timely manner when they show signs of wear or damage.

- Training: Ensure that personnel responsible for assembly and maintenance are adequately trained.

"Choosing the right bearing, paying attention to environmental conditions, and careful mounting and maintenance are critical to maximizing bearing life in your particular application.

Or describe your concern to us via our contact form: