Fröhlich & Dörken specializes in special rolling bearing solutions. Here you will always find new reports on how we have solved problems together with our customers. We can draw on a great deal of expertise, particularly in rolling bearing-based applications. We design a wide variety of hybrid bearings using different materials. We can design both the material and the geometry so that your application runs perfectly. We would be happy to advise you on site or in a TEAM meeting. We look forward to your challenge!

"Hybrid bearings as a solution for your application

"Maintenance-free bearings with Peek special cage

" Inner and outer ring made of stainless steel, balls made of ceramic

Special ball bearings for medical technology / laboratory technology

- Application of the customer

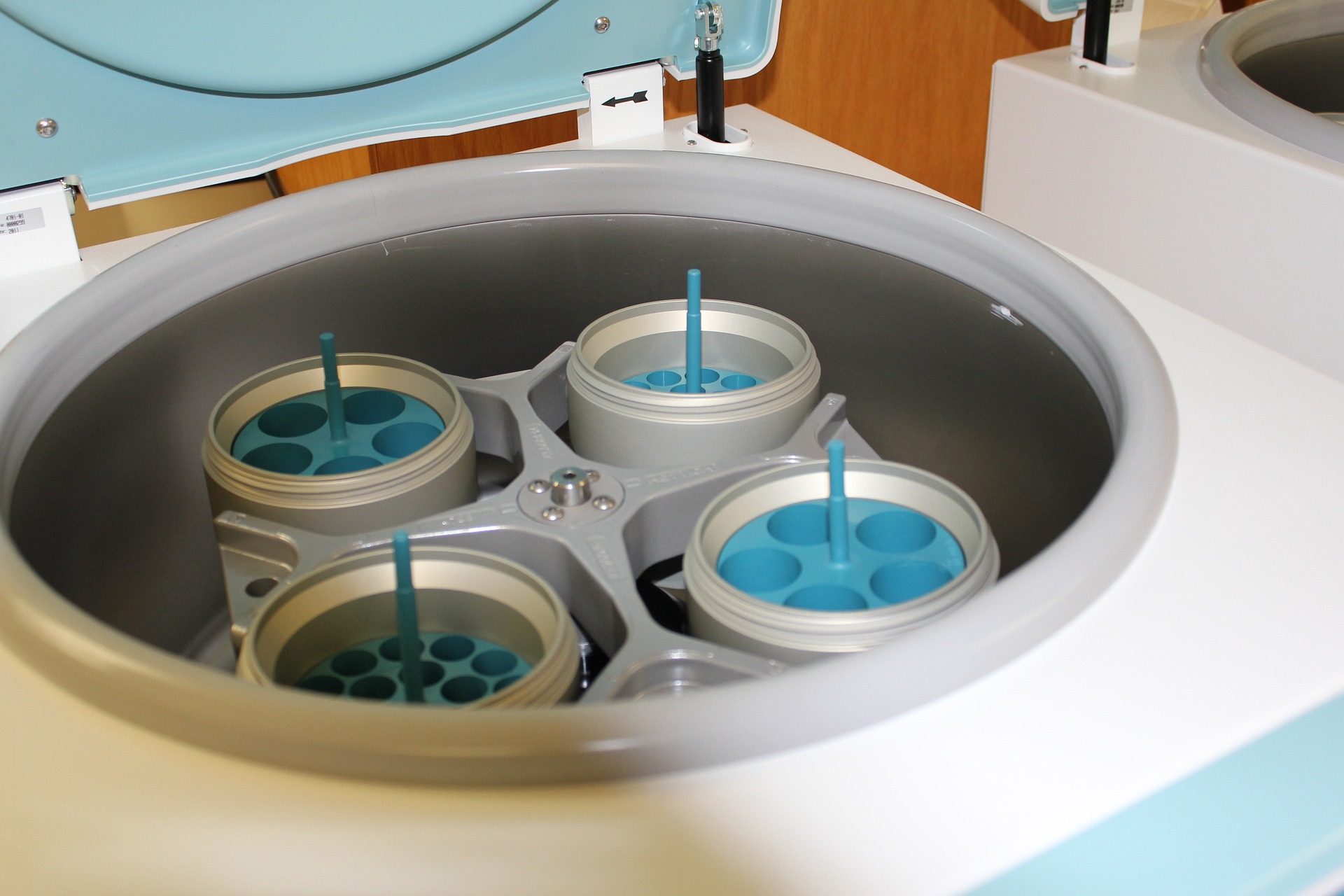

The customer we would like to introduce today is active in chemical medical technology. His products are used in laboratories and offer solutions in centrifugal technology. In medical laboratories, substances are centrifuged, which means sedimentation (separation) of different substances into their individual components. It is very important for the customers of our customer to get simple, efficient, durable, functionally based and sophisticated centrifuges. - Problem of the customer

In this application, the following challenges arise:

Due to centrifuging, there is a risk that the grease from the ball bearings will contaminate the samples. The grease escaping from the ball bearings due to centrifugal force could therefore contaminate the laboratory samples. This must be prevented at all costs. For this reason, the bearings are used without grease in this application. This in turn brings with it the problem that the ball bearings begin to rust. Without lubrication, the service life is also considerably shortened, among other things due to higher heat generation.

- Solution

But how can a ball bearing achieve its optimum service life without lubricant? Lubrication with rolling bearing grease is elementary for the service life. The ball bearing essentially consists of six components; inner ring, outer ring, cage, balls, grease and sealing washers. Based on our findings, we have optimised the following components: - Solution

We changed the material of the inner and outer rings to increase corrosion resistance. Stainless steel proved to be a more suitable material for this.

The geometry of the raceways corresponds to that of a four-point bearing.

In addition, we turned the ball bearing into a hybrid bearing by using ceramic balls. The only question left was the grease! Here our technical team did a great job. We selected a Peek special cage that solved this problem in an excellent way. The cage is composed of various components, which results in automatic lubrication without contaminating the laboratory samples. The cage now takes over the function of the lubricant. - Customer advantage

The customer was previously only able to solve the problems partially and only through complex assembly activities in his own work. This resulted in high labour costs. Due to the improved corrosion resistance, the service life of the rolling bearings has also increased significantly. In addition, the maintenance intervals of the products are significantly extended. Due to the longer service life of the bearings, our customer not only saves money, but we also save important resources and thus protect the environment.

Or describe your concern to us via our contact form: