Benefit from our strong partners like Schneeberger, NSK, and PMI. As an authorized dealer with over 75 years of experience, we offer you our comprehensive know-how in linear technology. We cover the entire linear program! Linear guides - guide rails and carriages in standard, narrow or wide, ball screws, etc. We are also happy to convert your products from Hiwin, SKF or Bosch-Rexroth and other manufacturers.

"Linear guides, ball screws and much more

"Fast and precise cutting of your splints

Linear technology for industry and wholesale

From pure linear guides and drive elements to complete systems ...

....from machine planning with customer-specific requirements, design to just-in-time delivery to your production ...

... FUD is at your side with professional solutions with over 75 years of experience in the most diverse applications of linear technology. Our satisfied customers from industry and trade measure us by the durability, availability and efficiency of our linear technology.

Here you can get an overview of the range of FUD products in the field of linear technology. Almost all types of linear guides from miniature to heavy-duty guides, complete linear systems, drive elements to gearboxes, etc.. All components are usually available quickly. In our Linear Centre, your guideways (rails) are assembled directly at our premises. Special dimensions or individually designed components, such as guide rails and carriages, are also available.

Especially in the consultation during the design phase and in the optimisation of your systems, with the goal of longevity and efficiency with low downtimes, you save time and money through our multi-layered experience in linear technology. Once we have found the right component for you, we supply your production reliably and just in time.

Our services

" Selecting linear technology correctly - These factors determine the selection of your components

Service life, efficiency and high precision of the executed movements are the success criteria of good and reliable linear technology. Our customers measure us by these characteristics. To ensure that your machine or system meets all expectations, it is necessary to select all components correctly.

This is particularly successful when the framework conditions and influences under which the linear technology is to be used are meticulously checked, assessed and included in advance...such as

- Mass to be moved

- Traversing speeds and accelerations

- Drive positions

- Travel (stroke)

- Centre of gravity

- Required precision such as positioning accuracy, running accuracies such as vertical or lateral runout

- Environmental influences such as ambient temperature / dust environment

- Available installation space in the machine

Contact our consultants directly to select your components individually according to your needs!

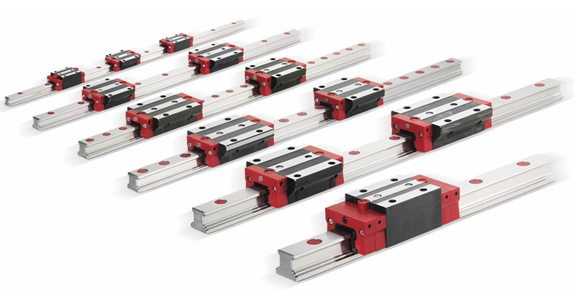

Determined by customer-specific requirements such as mass to be moved, required cycle times, movement speeds, available installation space, distance to be covered and many other factors, you will find the right solution at FUD. Our linear guides are available with or without integrated measuring systems.

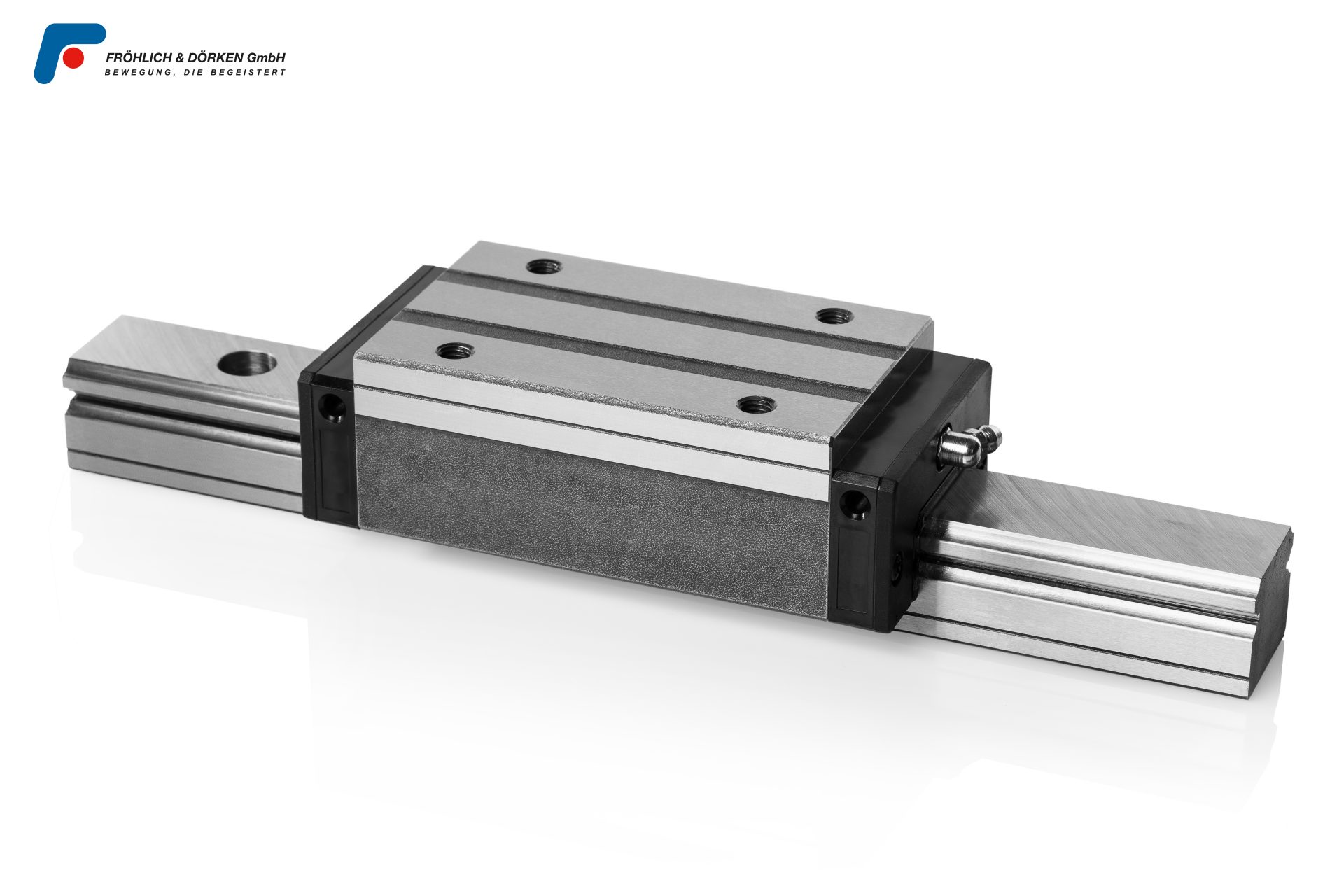

➥ Profile rail guides (with and without integrated measuring system)

- Ball Rail Systems

- Roller rail guides

- Miniature rail guides

- Rail guides

- with various corrosion coatings, also in stainless steel

- Various sealing options / long-term lubrication option

- according to customer drawing and in special specification

➥ Shaft guides / ball bush guides

- Linear ball bearing guides > Standard material and stainless steel

- Linear enclosure units > Standard and special specifications according to customer requirements and drawings

- Support rail shaft supports > Standard and special specifications according to customer requirements and customer drawings

- Shafts - standard material, chrome-plated and stainless steel

- Shaft blocks

➥ Roller guides

Manufactured according to your requirements and set backlash-free

- Guide rails

- Guide carriage

- Castors

- Pin

- Additional elements

➥ Linear guides with limited stroke

- Cross roller guides

- Flat cage guides

Linear technology also includes the drive elements that provide propulsion. These actuators are individually selected for the type of movement and power transmission required. For the various types of drive, suitable gears are often required for transmission. A planetary gear is often used here.

In order to save design time, the linear guide and drive are always combined together in a complete system ready for installation. Compliance with customer-specific parameters such as positioning accuracy, travel speed, repeatability, etc. is largely determined by the drive element.

➥ Drive elements

➥ Linear systems with drive

- Various drive and guide options

- Linear feed units - belt or ball screw (KGT)

- Precision positioning tables with ball screw drive

- Actuators with ball screw

- Linear axes

- Linear tables

- Linear motors

➥ Linear systems without drive

- Linear tables

- Miniature tables

➥ Planetary gear

- single-level

- multilevel

- Economy + precision quality

➥ Couplings

- elastic

- torsionally rigid

➥ Ball screws

- ground

- swirled

- rolled

Miniature ball screw

- up to Heavy Load Ball Screw

different qualities

- ground

- swirled

- rolled

Materials

- Standard materials

- Niro

- Various coating options

Drive

- driven spindle

- driven nut

End bearing

- Rolling bearing

- Bearing housing

End machining

- Without end machining

- with standard machining of the ends

- End machining according to customer drawing

Ball screw design completely according to customer specification

➥ Trapezoidal screw drives

Flange nuts

cylindrical nuts

various material also stainless steel

End bearing

- Rolling bearing

- Bearing housing

End machining

- Without end machining

- with standard machining of the ends

- End machining according to customer requirements

- Trapezoidal screw drive design completely according to customer requirements

➥ Racks and pinions

Precision

- milled

- ground

Gear quality up to Q4

- Pitch and single deviation fp=0.003mm

- Total pitch deviation fp=0.015/1000mm

Interlocking

- Standard straight toothed

- Helical gearing

- Customised racks

- up to module 20 with any cross-sections

Rack and pinion pitch

- metric

- Module division

Rack and pinion lengths

- one-piece racks up to 3000mm

Hardening processes

- soft

- nitrates

- Inductively hardened

- Case hardened and through hardened

" Buying linear technology - These are the questions interested parties ask us when looking for suitable components

By using linear technology, it is possible for machines to carry out precise, guided longitudinal movements and, for example, to precisely position a mass to be moved.

Just like bearings, which enable rotary movements of components, linear technology, is an essential part of industrial needs.

A usually electric, pneumatic or hydraulic drive generates a longitudinal movement via a drive element. The load is picked up and the mass to be moved is guided by a wide variety of linear guides which, for example, are connected by a connecting plate to form a carriage or slide. The mass to be moved can then be mounted and moved on this.

The movement is carried out as energy-efficiently as possible by means of the elements that today are mostly mounted on rolling element bearings. The rolling element guide minimises the force required for the movement. This means that even large masses can be moved with little effort and with high precision.

Due to a closed design of complete systems, they are not susceptible to contamination and are provided with integrated long-term lubrication, low-maintenance or even maintenance-free.

Main application areas of linear technology are main axes in machine tools, machines of all kinds such as production and conveyor systems, packaging machines, woodworking machines, sawing machines, measuring machines, machines in dental and medical technology, etc.

In addition, linear technology is used in any application in automation. In other words, wherever linear movements are to be carried out.

With over 30 years of experience in linear technology, the FUD experts have been able to build up a broad knowledge and experience in many areas. Used interdisciplinarily, they save you unnecessary mistakes and save you money.

Our project experience covers the following areas

- Drive technology

- Conveyor technology

- Mechanical Engineering

- Medical technology

- Food industry

- Laser systems

- Optics

- Electronics

- Machine tools

- Testing & Measuring Machines

- Assembly systems

- 3D printing

- Plant engineering

- Semiconductor

- Solar

We offer linear technology in different materials. These include steel, stainless steel, aluminium and plastic. Together we will find the right material for your requirements.

Steel

Stainless steel

Aluminium

Plastic

Especially in such an individual and consultation-intensive field as linear technology, we always recommend that you first talk to us directly. Only in personal contact can you describe your needs, goals and general conditions in detail and directly ask our experts important questions about your project. This approach provides you with reliable information very quickly, enabling you to start your procurement or design project easily and reliably.

- Get in touch with us by phone or e-mail - together we will discuss initial solutions for you

- Send us your CAD data as well as your requirement definition

- Internally, we then prepare a proposal for an ideal solution for you. Depending on your order, we carry out a service life calculation in addition to the design of the required components

- Together we will discuss our proposed solution with you and provide any necessary design support

- After you have decided on a solution, we agree on prices and delivery times

Our long-term partners involve us in their planning and projects at a very early stage for a variety of reasons. Already in the planning phase of a machine or plant, we can provide concrete design support with our many years of experience and give helpful hints that will save you a lot of time and money, as you will not encounter any unexpected problems when operating the machine or plant.

Of course, our guide rails are cut and assembled directly in our factory according to your wishes.

Thanks to a broad stock of goods in our central warehouse in Sprockhövel, we can quickly supply you with the components you need. It is even better for your procurement if you secure your requirements through call-off contracts and have FUD deliver to your production just in time, as required.