Strict hygiene regulations are essential in the food industry. Accordingly, storage technologies must also meet high standards in order to meet the requirements for cleaning processes with high-pressure cleaners, alkalis or sterilizing liquids. Bearing components must also offer maximum reliability in the event of extreme temperature fluctuations, such as those encountered in sterilization or baking processes. Our stud type track rollers, yoke type track rollers and flanged rollers as well as bearing components are specially designed to meet the requirements of the food industry. By using food-grade lubricants and sealing techniques that can be used at temperatures up to 260°C, as well as corrosion-resistant coatings or stainless steel materials, we offer the highest level of safety and quality. Thanks to our advanced bearing technology, we can guarantee long service lives while ensuring maximum freedom from maintenance. Our bearings are not only maintenance-friendly, but also extremely resistant and durable.

"Increase in production due to low

maintenance effort

" unhesitating use in the

food industry

" no grease disposal necessary

" Environmentally friendly

Rolling Bearings / Track Rollers for Food / Food Industry

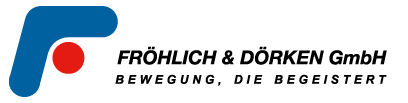

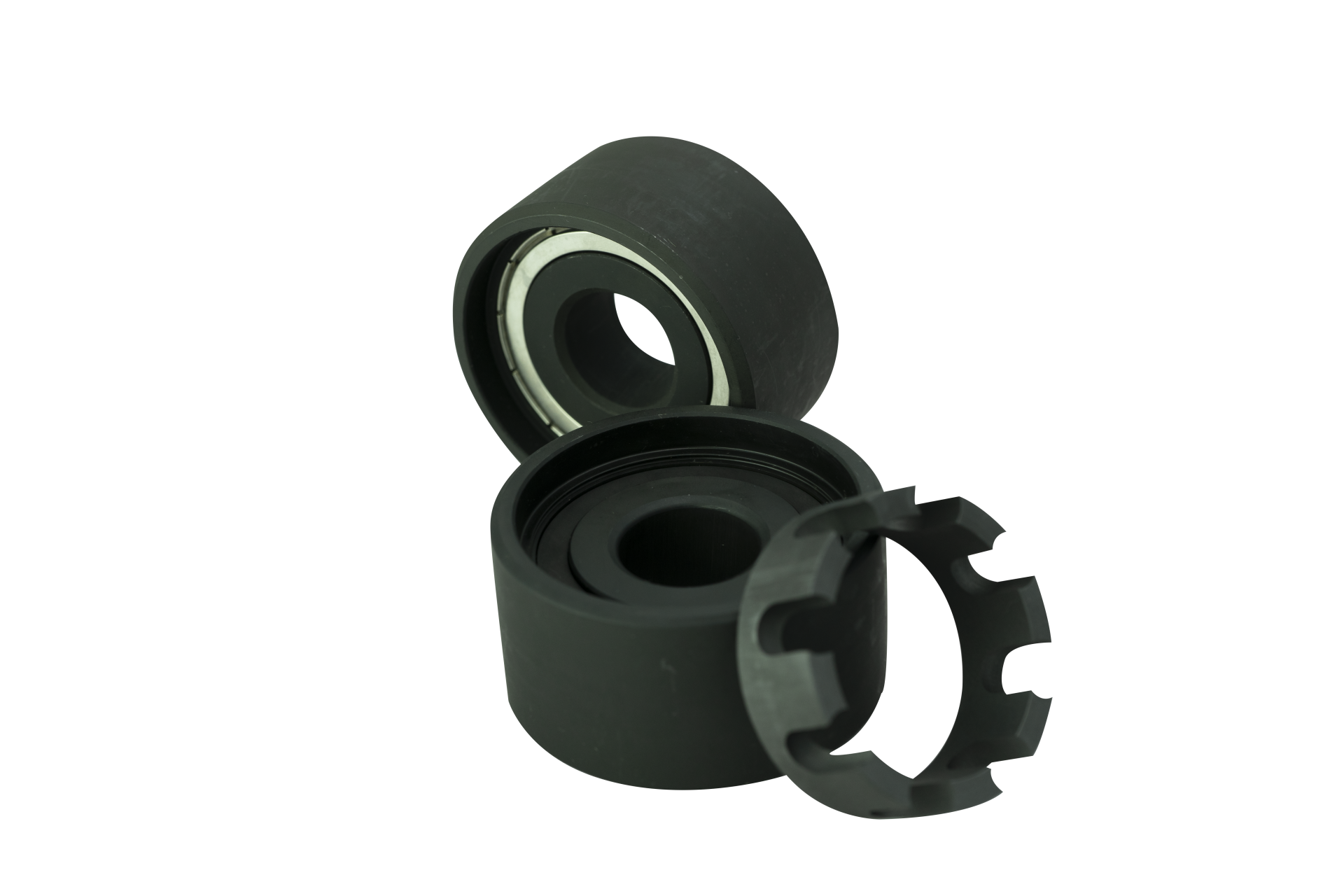

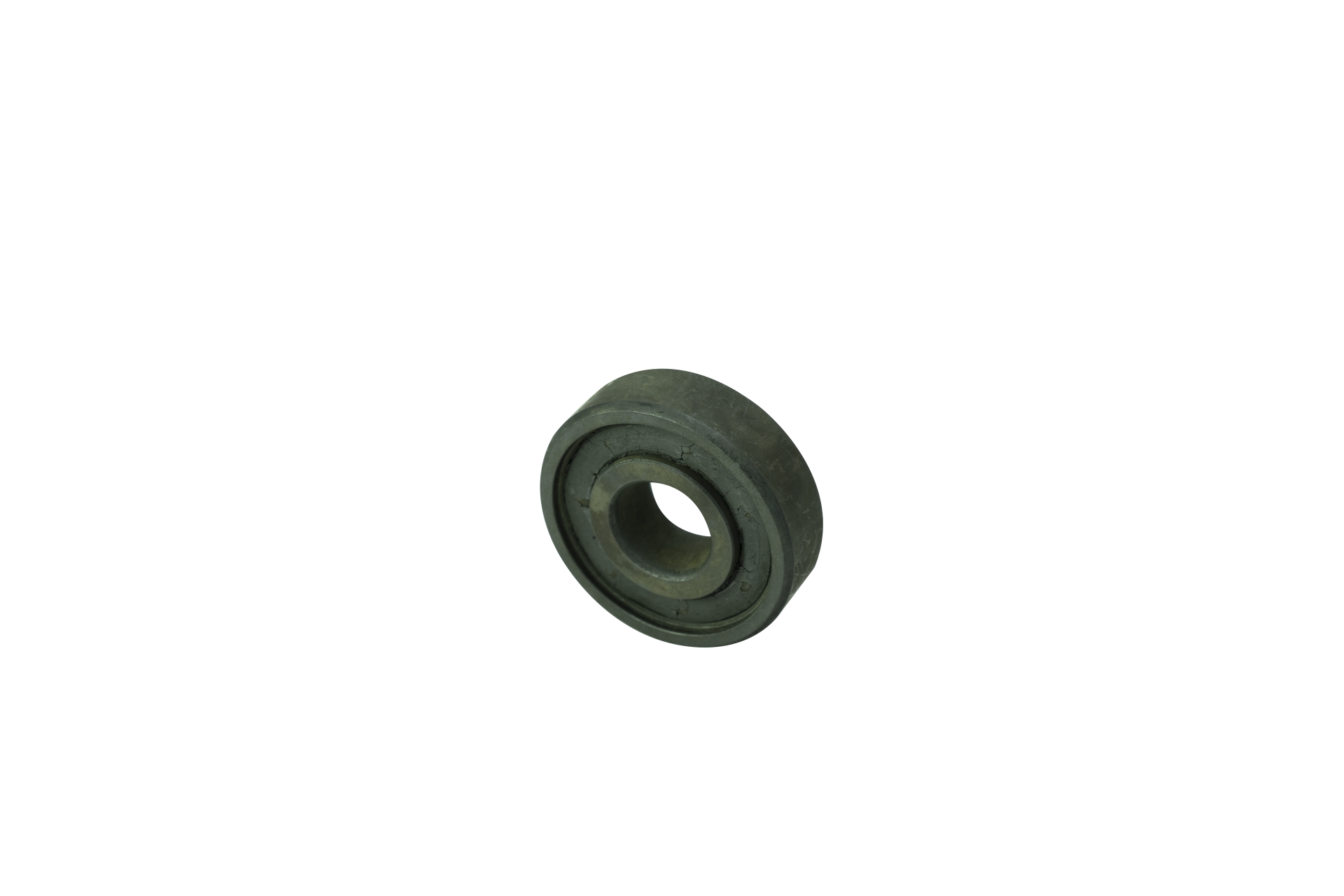

FUD specific maintenance-free rolling bearings for food processing machinery

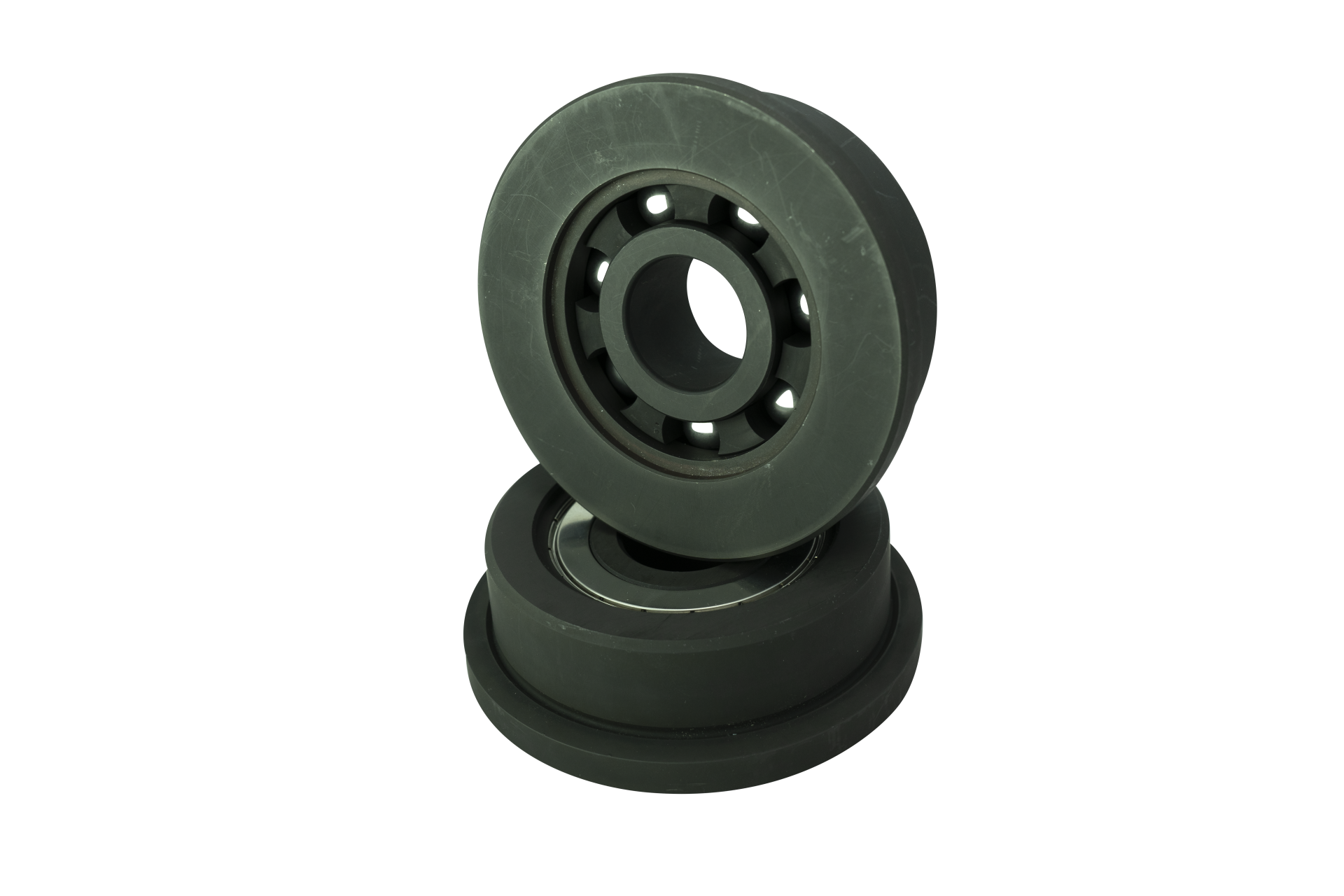

In the food processing machinery sector, many of our customers use a rolling bearing with a graphite cage. Both at high temperatures and under normal temperature conditions.

The bearings manufactured by FUD are equipped with a graphite cage, are maintenance-free and meet the requirements of the FDA regulation "Code of Federal Regulation Title 21 ( CFR 21 ), § 170.39".

In the industrial sector, rolling bearings are filled with solid lubricant. Our rolling bearings are either equipped with a graphite cage or filled with a solid graphite mass and are maintenance-free. Applicable up to 400°Cdepending on the design.

We manufacture for well-known customers in the field of food machinery.

We produce flanged rollers with graphite cage, track rollers with graphite cage and track rollers with graphite filling. Send us your drawing and a sample. We will then make you our offer without any obligation and free of charge.

In the case of an order, we stock your product with us in Sprockhövel, so that we can supply you punctually according to your specifications.

When we think of sweet treats, we think of delicious baked goods and crispy cookies. But behind the scenes, extreme conditions prevail: temperatures of up to 260°C, contact with baking residues, wafer dust, high humidity and fats are the order of the day. Storage technology in wafer baking machines faces a major challenge. We are working hard to find solutions that meet these requirements while meeting the highest quality standards. But what does the phrase "having one on your waffle" actually mean? Read the solution on the website of the German Language Society.